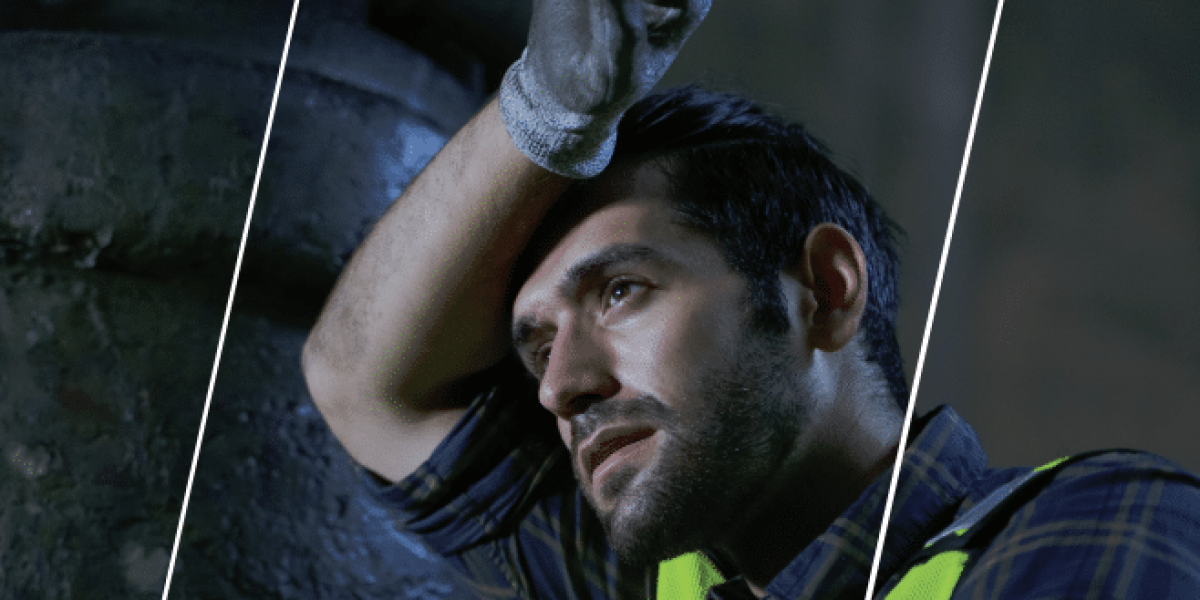

Rising Temperatures. Rising Workplace Accident Rates.

With rising global temperatures, companies are developing ever more innovative ways of tracking and monitoring workers to ensure their safety. Using a combination of wearable devices and tracking software, businesses are able to monitor workers’ health in real-time, and then use this data to better inform policy and safety measures. In September 2023, when daytime temperatures in the UK exceeded 30°C centigrade for seven consecutive days, it was clear, claimed meteorologists, that socalled ‘once in a decade’ periods of extreme heat were starting to become much more frequent. A year earlier the mercury broke 40°C in Britain for the first time ever (when five official heat-wave periods were declared, and overnight temperatures stayed above 25°C). Meanwhile, in 2020, maximum temperatures hit 34°C for six consecutive days. Between 2002-2022, the UK has experienced its 10 hottest years ever.

But while it’s the much smaller average temperature rises across a whole year that tend to occupy the policies of politicians and climate campaign groups, it’s the sheer number of extreme heat events (and the impact these have on employees expected to cope with them) that is now causing worry. Every time staff experience working conditions where ambient temperatures are above 30°C, research suggests it correlates to a 5-7% rise in accident rates, and a 10-15% rise in accidents when temperatures rise above 38°C (Narocki, 2021). This is because the body’s own ability to regulate its core temperature becomes severely compromised. Blood vessels expand, blood pressure falls and dizziness and inability to concentrate sets in rapidly. Compared to 1961-1990 averages, data shows hot days (those above 28°C+) have doubled in frequency, while very hot days (30°C+) have tripled. Hot days are now expected to increase four-fold, while the chances of reaching 40°C will reduce from being the one in 1,000 chance they were in 1970 to one in 15 chances by 2090.

“Every time staff experience working conditions where ambient temperatures are above 30°C, research suggests it correlates to a 5-7% rise in accident rates.”

Wearable Technology and EHS Software Solutions for Real-Time Heat Stress Prevention

Workers that are most impacted by these sorts of temperatures are of course those who predominantly work outside. However, extreme heat can also exist in industrial settings and mines, and can even impact urban workers in non-air-conditioned buildings – where temperatures can be as much as 10°C warmer due to the ’urban heat trap’ effect. Either way, more workers are dealing more often with high heat. Historically though, employers have been slow to respond to the dangers of excess heat. The HSE simply advises employers to consider the impact on staff from six main areas including air movement, air temperature, humidity, clothing and metabolic heat with the emphasis on working ’around’ heat, rather than reducing it. Where they exist, temperature reading gauges can be ineffective if put in the wrong place, while even on-body devices may not alert workers to dangers they may be facing before they start feeling affected by heat.

It’s for these reasons that Zack Braun, CEO of SlateSafety – a provider of a real-time wearable safety armband that is used for heat stress, lone worker, and confined space safety – has recently joined forces with a provider of cloud-based Environmental, Health, Safety (EHS), and Sustainability software solutions, Benchmark Gensuite. Together, they aim to combine data streams and foster faster decision-making when employees might be at risk. “Our wearable technology will alert a worker – in real-time – if their core body temperature exceeds safe thresholds,” says Braun. “But what has been historically lacking in the safety industry – and what the partnership provides – is the ability to send these alerts directly to Benchmark Gensuite’s platform, where environmental health and safety directors/advisors can view the data, analyse it in real-time, and find hotspots, or trouble zones.”

According to Braun, real-time sensing, such as through a wearable device, can be used to produce actionable insight or even predictive analytics, where data can feeds into Benchmark Gensuite’s Risk AI engine, for example – looking for trends and finding how heat stress can even be prevented. SlateSafety’s own technology now incorporates fall-detection and no-movement sensors. The partnership with Benchmark Gensuite means these new features can be flagged to leadership on its system too. As Pete Bolderstone, Leader, Global Partner Program, Benchmark Gensuite concurs: “There’s the wearable itself, which has to be capable of detecting adverse conditions and situations where an alert needs to be triggered. But then there’s also the fact that an alert does itself need to be listened to or heard by somebody or acted upon by somebody.”

Continuously Evolving Solutions for an Evolving Regulatory Landscape

As a company based in Atlanta, Georgia, SlateSafety knows all about extreme heat. In 2023, Atlanta suffered its second-hottest year in almost a century, and between 1980-2009 it recorded the most US deaths due to extreme heat. In 2023, the city published its first heat vulnerability study, looking specifically into how people in the city’s neighbourhoods could be susceptible to extreme heat. One lasting legacy of the Biden administration could be the implementation of a proposed rule that aims to protect approximately 36 million workers in indoor and outdoor work settings and substantially reduce heat injuries, illnesses and deaths in the workplace. “The heat wearables market is growing tremendously due to state-specific laws as well as federal standards now being passed,” says Braun. He adds: “Heat doesn’t just impact outdoor workers. For example, in the steel industry there’s heat already, but on top of this workers are wearing PPE, which can cause them to overheat faster. Often, people can be so focused on their work, that they don’t notice it – which is why our link up with Benchmark Gensuite is so critical now.”

Originally SlateSafety’s monitoring solution started as an in-ear device, a bit like an earphone. This was mainly because the human ear has lots of blood vessels and is generally a good place for sensors to record lots of different biometric data. But this was soon changed to an armband after the development team realised the challenges of building for various ear shapes. (Plus, it wasn’t always practical for many workers to have something in their ear all the time.) Version 2 of the product – its current version – has a sensor that sits against someone’s skin, and once it’s turned on, it automatically starts sending data over the cellular network.

Running the Pilot

One employer already benefiting from the partnership is pharmaceuticals and healthcare company, Perrigo. In one of its lines of business, it manufactures baby formula – which requires staff to work around huge, hot, seven-storey drying towers. It had a specific need to both manage and prevent incidents relating to heat stress. During a pilot period, workers – who were also wearing heavy personal protective equipment – were equipped with the wearable band. When an alert occurs on SlateSafety’s wearable, the data is sent to Benchmark Gensuite’s concern reporting and near miss reporting processes, triggering notifications to key stakeholders when configurable threshold limits for core body temperatures and heart rate readings were being exceeded. These incidents were also automatically logged. During the test phase, Perrigo’s environmental health and safety leaders could leverage Benchmark Gensuite’s dashboards and analytics to gain a holistic view of real-time statuses and insights into heatrelated concerns and risks. This included providing them with a highly visual heat map dashboard to equip EHS leaders with the ability to better spot any patterns or trends within the data.

Results That Do the Talking

According to Braun, when the pilot period ended and the armbands were taken away, staff demanded to have them reinstated because they said having the technology made them feel safer. Eventually, the bands were returned to the staff and an analysis of the data they had collected has since confirmed that the employees’ instincts about their safety and protection was indeed correct. Since implementing SlateSafety and Benchmark Gensuite at two of its sites, Perrigo reported that three heat-related incidents have been prevented per week – such that the company has now suffered no heatrelated injuries in the last three years. During this period, more than 191 concern reports have been created by data transmitted from SlateSafety to the Benchmark Gensuite platform. But the real-time nature of the oversight has meant Perrigo has been able to act on risk alerts early – to the extent that the company has now achieved more than 140,000 safe hours worked without a single heat-related lost workday case.

“When workers begin to suffer from heat exhaustion, they start to lose water and salts from their body, and if this isn’t treated quickly, it can lead to heat stroke” access critical information in realtime,” says Bolderstone. He adds: “Perrigo’s metrics are great for any other organisation looking in. With our measuring technology, the number of heat stress incidents is zero. Without the technology, it’s going to be more than zero. And anything more than zero means somebody is getting hurt. And that’s not what we want to be seeing happen here.”

Why Early Detection of Heat Stress Matters

When workers begin to suffer from heat exhaustion, they quickly start to lose water and salts from their body, and if this isn’t identified and treated quickly, it can lead to heat stroke – which is far more serious, where life-threatening strain can be put on the body’s brain, lungs, kidneys and liver. Here workers can quickly become confused and disorientated. Heat stroke can also cause seizures and loss of consciousness – dangers that are exacerbated if that person is a lone worker, or is working from height. “When something goes wrong, somebody is alerted to it right away and is able to make a decision that ultimately could help avoid injury and prevent an incident. This is a great addition to any company’s safety mandate,” says Bolderstone.

Steve Belin, Executive Director of Product Management, Benchmark Gensuite adds: “In this situation, it’s a case of the more data, the better. With the types of alerts we are able to receive, issues can be identified. EHS officers can determine whether the data is a blip, and at what point certain repeated data becomes a trend. These trends can be worked through with AI and machine learning to really separate the trends and the major issues from a one-time spike. By having larger data sets, it helps do those analyses more accurately.”

A Wide Range of Applications for Faster, Better Decisions

Not surprisingly, the technology partnership is already being applied to a much wider range of situations than initially planned to improve different organisation’s safety decision-making. “One partner is a factory in the northwest of the US,” says Braun – who describes the technology as providing a “shepherding” role for organisations. He adds: “One of its workers is a lone worker, and he’s actually a deaf worker too, so he can’t really communicate over the radio to let someone know if he needs help. If he falls, the wearable can alert someone. He can also double tap the wearable to send a request for help. The technology continues to surprise me. When we originally started the company seven years ago – we were mainly targeting the military. Back then, I would never have imagined how this could be a vital safety measure for a deaf or handicapped lone-worker.” Clearly, while there are some areas of health and safety that are difficult to reach incidents in, with heat sensing technology and the ability for supervisors to act quickly on actionable data, zero accidents ’can’ be achieved.

“Zero incidents really is achievable,” asserts Bolderstone. “Companies just have to keep chipping away at it, and understand that this [technology] is the cost of sending their workers home safely.” Braun agrees: “The best companies we work with already have a strong safety culture in place. The worst thing for us is if someone buys the system, and then puts it in the closet where it just sits and gathers dust. That’s why we tend to adopt a pilot approach – where we give clients armbands to use, so they can actually try them out. When this happens, companies pretty much demand the devices back. Workers already know they’re doing a dangerous job; they just want added protection while they’re doing that job.” Concludes Bolderstone, “It’s worker safety that we’re talking about here. This is not just a data gathering exercise. It’s about making sure people get home safely to their families every night. I think the future is very bright in terms of what we’re trying to do here.”

This article was originally published in the Winter 2024 edition of Health & Safety International (HSI) by Peter Crush.