Maintain a comprehensive, centralized record of all safety-critical devices (eye wash stations, fire extinguishers, cranes, hoists, etc.) and/or equipment (lathes, drilling machines, etc.), ensuring you never lose track of your most valuable assets.

Effortlessly schedule ad-hoc or recurring maintenance tasks by equipment, department, or location, keeping your equipment in top condition and preventing costly downtime.

Manage work order requests with ease, ensuring a balanced workload for your maintenance technicians and minimizing delays.

Create flexible, point-of-action checklists that empower your team to execute tasks with precision and efficiency to streamline procedures for consistent performance.

Leverage automated email alerts to ensure that no maintenance tasks go past due, keeping your operations on track.

EHS Director and Maintenance Manager

Brian, Safety and Risk Manager

Martha, Director, Environmental Health & Safety

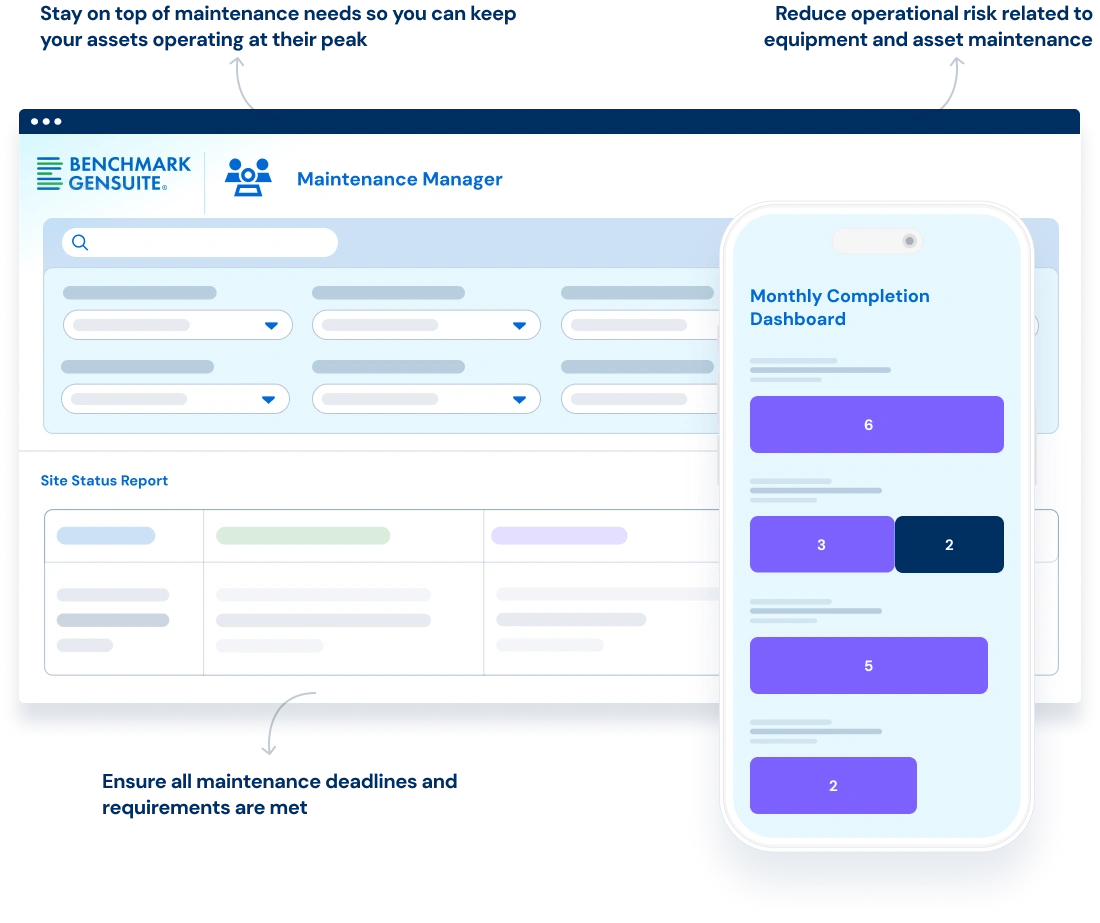

Stay up-to-date on maintenance and compliance needs with integrated scheduling tools.

Drive participation with integrated LOTO procedures.

Track assets with a viewable inspection history.

Digitally document permits, maintenance records, and SOPs.