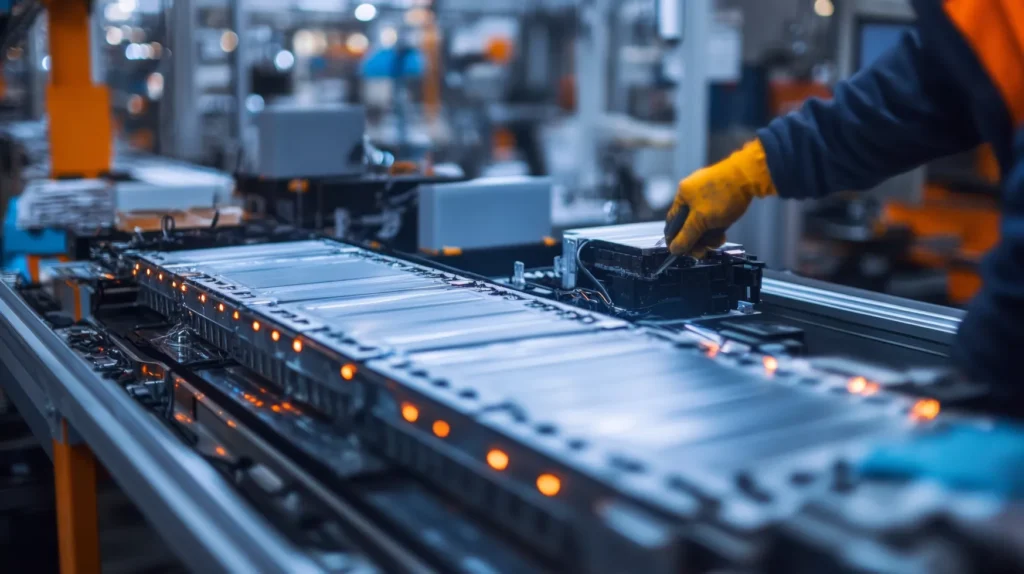

Manufacturing drives economies and innovation — but it also carries inherent risks. In a sector where precision and speed are everything, safety failures can ripple through the entire operation. Production slows. Costs rise. Morale dips.

A strong safety culture doesn’t just prevent incidents — it improves efficiency, quality, and trust across every shift and site. Organizations that digitize and proactively manage safety programs consistently see:

“Manufacturers with proactive safety systems see up to 40% fewer incidents and 25% faster recovery from operational disruptions.”

These results don’t come from reacting — they come from anticipating risk. That’s where AI and connected safety management systems make all the difference.

Common challenges include:

Each of these issues reduces visibility and slows response time — making it harder to identify risks before they escalate.

By moving to a digitally connected EHS ecosystem, manufacturers can bridge these gaps, automate data collection, and transform every safety report into an opportunity for prevention.

Explore how Benchmark Gensuite’s Incident & Injury Management and Audit & Inspection Management tools unify reporting, analysis, and follow-up.

Guides users in real time, flagging incomplete or unclear incident reports and suggesting improvements before submission. This ensures to better data, faster reviews, and fewer delays.

Takes safety to the next level — from insight to action.

Agents automate document uploads, extract regulatory requirements, assign tasks, and track completion, closing the loop between issue identification and resolution.

Learn more about Genny AI and how it powers real-time safety insights across industries.

At TK Elevator, Benchmark Gensuite’s AI-powered quality and safety tools delivered measurable impact:

Metric | Before AI | After AI |

|---|---|---|

Issue closure rate | <50% | 97% |

Average cycle time | 120 days | 20 days |

Cost savings | — | $20.2 million |

AI didn’t just make processes faster — it built a culture of accountability and trust, where reporting leads directly to action and every team feels empowered to improve safety performance.

A thriving safety culture is one where every worker’s input matters, and data transparency builds trust. With AI-powered systems, employees see faster responses to their reports, closing the feedback loop and reinforcing engagement.

Genny AI helps teams:

“Creating a culture of safety in manufacturing requires both technology and trust.”

By combining human awareness with AI precision, manufacturers can evolve from compliance-driven to culture-driven safety excellence.

Safety leadership in this new era means using data not just to measure — but to predict, prevent, and protect.

See how our Risk AI & Predictive Analytics tools help identify risks before they impact operations.

Incident & Injury Management

Risk AI & Predictive Analytics

Sustainability and ESG Reporting

Audit & Inspection Management

Permit & Compliance Automation